NinjaTek’s TPU filament is synonymous with quality in 3D printing circles and the material of choice for discerning makers. Available Colors: Black, white, gray, red, orange, yellow, green, blue, transparent.Price: Check price at Matterhackers here / Amazon here.When you buy through links on our site, we may earn an affiliate commission. Soft PLA blends PLA with TPU for a best of both worlds material.įor more in-depth details about each of these different types of flexible filament, be sure to check out our complete flexible filaments 3D printing guide.ģDSourced is reader-supported. They are also formulated to offer better elasticity. PLA Blends – PLA+ and Soft PLA are PLA filaments designed to reduce the natural brittleness of standard PLA to increase their durability and impact resistance. TPC is usually printed with powder bed fusion printers.

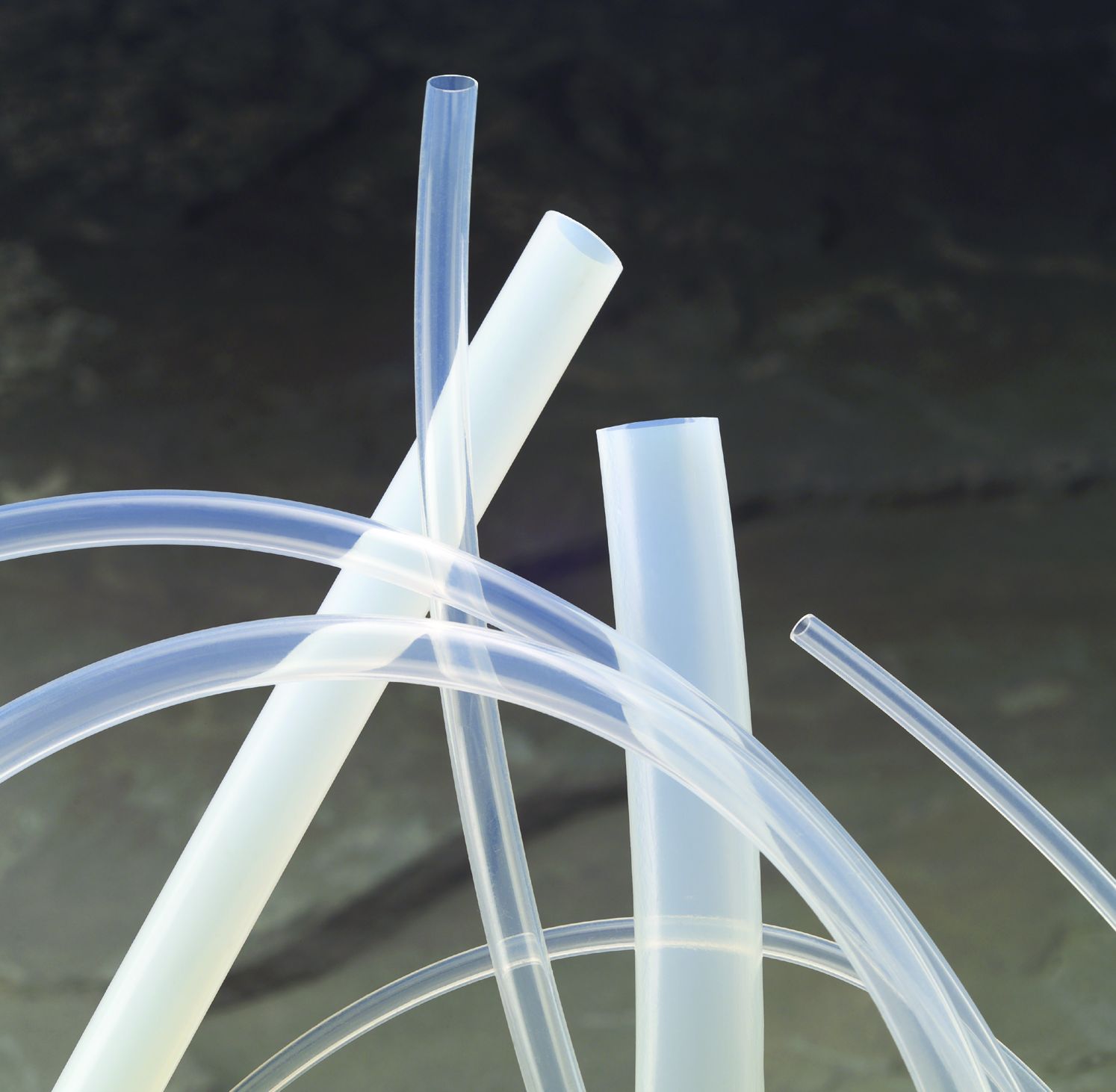

It’s not as elastic as TPU, but it’s considerably tougher and stronger, along with boosted resistance to chemicals and high temperatures. TPC – Thermoplastic Co-Polyester is an industrial-grade flexible, generally used in fields such as medicine. TPU also has superb resistance properties, covering chemicals, abrasion, temperature, vibration, and impact. It’s more rigid than straight TPE, which eases the printing processes, hence why makers favor it. TPU – ThermoPlastic Polyurethane is the most commonly used flexible for 3D printing. TPE – ThermoPlastic Elastomer is an umbrella term for a cross-section of flexibles, including TPU, that regroups the properties of rubber into a plastic polymer. Some surfaces like PEI can stick too well, so be wary of that. Use the right bed surface: a thin coating of glue stick gives great results.Check your slicer settings to optimize for this. Retraction settings: flexible can leak more than standard filaments between extruding points.If filament oozes and over extrudes, turn the temperature down if it’s under extruding, turn the temperature up.

Check your temperature: TPU and flexible filaments print at anywhere between 210-260☌, depending on the blend.Direct drive extruders also work better, as Bowden tubes can cause extra friction. Print slowly: 20-40mm/s is a good starting point for most flexible.

#Best material for flexture how to

How to 3D Print Flexible Filament (TPU/TPE) – Tips

0 kommentar(er)

0 kommentar(er)